Essential Guide: Air Brake Maintenance Tips;

26-Jul-2024

Understanding Air Brake Systems: Components and Functionality

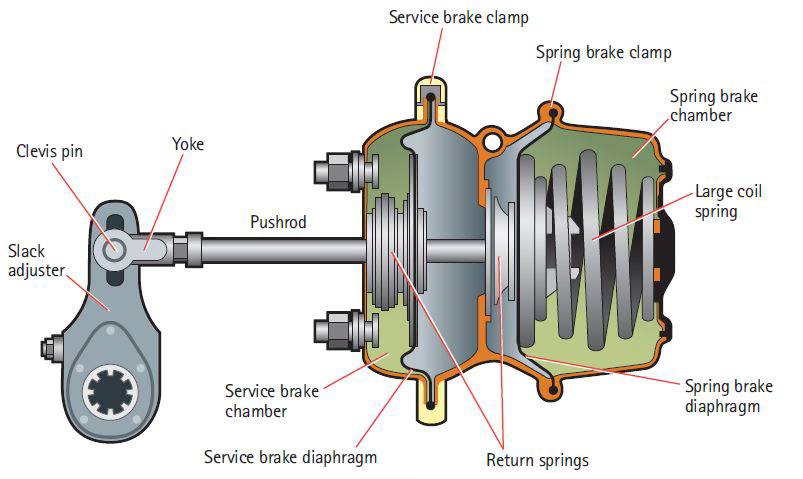

Proper understanding of air brake systems is crucial for maintaining the safety and functionality of your vehicle. Air brake systems are composed of various components that work together to enable effective braking. These components include the compressor, air reservoirs, brake chambers, slack adjusters, and brake shoes. Understanding how each component functions and interacts with the others is essential for troubleshooting and maintaining your air brake system.

One important component of the air brake system is the compressor. The compressor is responsible for generating compressed air that is used to activate the brakes. It is important to ensure that the compressor is properly lubricated and free from any leaks or damage.

Another crucial component is the air reservoirs, which store the compressed air. Regularly checking the air reservoirs for leaks and ensuring that they are properly pressurized is essential for maintaining optimal brake performance.

Brake chambers are another important part of the air brake system. These chambers convert the compressed air into mechanical force that is applied to the brake shoes, resulting in braking action. Regular inspection of brake chambers is necessary to identify any signs of wear or damage.

Slack adjusters play a key role in maintaining proper brake shoe-to-drum clearance. It is important to regularly inspect and adjust the slack adjusters to ensure that the brakes are engaging properly and wearing evenly.

Lastly, the brake shoes are the components that come into contact with the brake drum to create friction and slow down the vehicle. Regularly inspecting the brake shoes for wear and replacing them as needed is crucial for maintaining effective braking performance.

By understanding the components and functionality of air brake systems, you will be better equipped to perform routine maintenance and address any potential issues that may arise.

Routine Checks: What Every Driver Should Know

Performing regular checks on your air brake system is essential for ensuring its proper functioning and preventing potential issues. As a driver, there are several key checks that you should be familiar with to maintain the safety and performance of your vehicle.

Firstly, it is important to regularly check the air pressure in the system. Low air pressure can lead to ineffective braking and compromised safety. Using a reliable air pressure gauge, check the pressure in the air reservoirs and ensure that it is within the recommended range.

In addition to checking the air pressure, it is crucial to inspect the air lines and fittings for any signs of leaks or damage. Leaks can result in loss of air pressure and reduced braking effectiveness. If you notice any leaks or damage, it is important to address them promptly.

Another routine check that every driver should perform is the inspection of brake adjustment. Proper brake adjustment is essential for optimal braking performance. Use the appropriate tools to measure the brake shoe-to-drum clearance and adjust the slack adjusters as needed.

Regularly inspecting the brake shoes for wear is also important. Worn brake shoes can lead to reduced braking efficiency and increased stopping distance. If you notice significant wear on the brake shoes, they should be replaced promptly.

Performing routine checks and addressing any issues promptly will help ensure the safety and performance of your air brake system.

Addressing Common Air Brake Problems

Despite regular maintenance and checks, air brake systems can still experience issues. It is important to be aware of common air brake problems and know how to address them to maintain the safety and functionality of your vehicle.

One common problem is air leaks. Air leaks can occur in various parts of the air brake system, such as the air lines, fittings, valves, and connections. If you notice a hissing sound or a drop in air pressure, it is likely that there is an air leak. Inspect the system thoroughly to identify the source of the leak and repair or replace the affected components.

Another common issue is brake fade. Brake fade occurs when the braking performance decreases over time or under specific conditions, such as prolonged braking or driving downhill. This can be caused by overheating of the brake components or worn brake shoes. To address brake fade, it is important to allow the brakes to cool down and avoid prolonged or excessive braking. If brake fade persists, it may be necessary to replace the brake shoes.

Frozen brake lines can also be a problem in cold weather conditions. When the moisture in the air brake system freezes, it can prevent the brakes from activating properly. To prevent frozen brake lines, it is important to use the appropriate air dryer system and perform regular maintenance to remove moisture from the system.

By being aware of these common air brake problems and knowing how to address them, you can ensure the continued safety and functionality of your air brake system.

Seasonal Maintenance for Optimal Air Brake Performance

In addition to regular checks and maintenance, seasonal maintenance is important for optimal air brake performance, especially in extreme weather conditions.

During the winter months, it is important to take extra precautions to prevent freezing of the air brake system. Inspect the air dryer system and replace any desiccant cartridges as needed. Ensure that the air lines and fittings are properly insulated to prevent freezing. Additionally, use the appropriate winter-grade brake fluid to prevent freezing of the brake lines.

In hot weather conditions, thermal expansion of the air brake system components can occur. This can lead to increased brake shoe-to-drum clearance and reduced braking performance. To prevent this, regularly inspect and adjust the slack adjusters to ensure proper brake shoe-to-drum clearance.

Seasonal maintenance also includes checking and adjusting the brake shoe lining thickness. In extreme weather conditions, the brake shoe lining can wear faster. Regularly inspecting the lining thickness and replacing the brake shoes as needed will help maintain optimal braking performance.

By performing seasonal maintenance tasks, you can ensure that your air brake system is prepared to handle the specific challenges posed by different weather conditions.

Professional Inspection and Maintenance: When to Call the Experts

While regular maintenance and checks can go a long way in ensuring the safety and performance of your air brake system, there are times when it is necessary to seek professional inspection and maintenance.

If you encounter any significant issues or problems that you are unable to address or diagnose on your own, it is recommended to consult a professional. They have the expertise and specialized tools to thoroughly inspect and diagnose any complex issues with your air brake system.

Additionally, it is important to adhere to any manufacturer recommendations for professional inspections and maintenance. These recommendations may include specific intervals for professional inspections or requirements for specific maintenance tasks. By following these recommendations, you can ensure that your air brake system receives the necessary professional attention to maintain its optimal performance and safety.

Remember, the safety of your vehicle and everyone on the road depends on the proper functioning of your air brake system. When in doubt, it is always better to seek professional assistance to address any concerns or issues.Essential Guide: Air Brake Maintenance Tips;

Understanding Air Brake Systems: Components and Functionality

Proper understanding of air brake systems is crucial for maintaining the safety and functionality of your vehicle. Air brake systems are composed of various components that work together to enable effective braking. These components include the compressor, air reservoirs, brake chambers, slack adjusters, and brake shoes. Understanding how each component functions and interacts with the others is essential for troubleshooting and maintaining your air brake system.

One important component of the air brake system is the compressor. The compressor is responsible for generating compressed air that is used to activate the brakes. It is important to ensure that the compressor is properly lubricated and free from any leaks or damage.

Another crucial component is the air reservoirs, which store the compressed air. Regularly checking the air reservoirs for leaks and ensuring that they are properly pressurized is essential for maintaining optimal brake performance.

Brake chambers are another important part of the air brake system. These chambers convert the compressed air into mechanical force that is applied to the brake shoes, resulting in braking action. Regular inspection of brake chambers is necessary to identify any signs of wear or damage.

Slack adjusters play a key role in maintaining proper brake shoe-to-drum clearance. It is important to regularly inspect and adjust the slack adjusters to ensure that the brakes are engaging properly and wearing evenly.

Lastly, the brake shoes are the components that come into contact with the brake drum to create friction and slow down the vehicle. Regularly inspecting the brake shoes for wear and replacing them as needed is crucial for maintaining effective braking performance.

By understanding the components and functionality of air brake systems, you will be better equipped to perform routine maintenance and address any potential issues that may arise.

Routine Checks: What Every Driver Should Know

Performing regular checks on your air brake system is essential for ensuring its proper functioning and preventing potential issues. As a driver, there are several key checks that you should be familiar with to maintain the safety and performance of your vehicle.

Firstly, it is important to regularly check the air pressure in the system. Low air pressure can lead to ineffective braking and compromised safety. Using a reliable air pressure gauge, check the pressure in the air reservoirs and ensure that it is within the recommended range.

In addition to checking the air pressure, it is crucial to inspect the air lines and fittings for any signs of leaks or damage. Leaks can result in loss of air pressure and reduced braking effectiveness. If you notice any leaks or damage, it is important to address them promptly.

Another routine check that every driver should perform is the inspection of brake adjustment. Proper brake adjustment is essential for optimal braking performance. Use the appropriate tools to measure the brake shoe-to-drum clearance and adjust the slack adjusters as needed.

Regularly inspecting the brake shoes for wear is also important. Worn brake shoes can lead to reduced braking efficiency and increased stopping distance. If you notice significant wear on the brake shoes, they should be replaced promptly.

Performing routine checks and addressing any issues promptly will help ensure the safety and performance of your air brake system.

Addressing Common Air Brake Problems

Despite regular maintenance and checks, air brake systems can still experience issues. It is important to be aware of common air brake problems and know how to address them to maintain the safety and functionality of your vehicle.

One common problem is air leaks. Air leaks can occur in various parts of the air brake system, such as the air lines, fittings, valves, and connections. If you notice a hissing sound or a drop in air pressure, it is likely that there is an air leak. Inspect the system thoroughly to identify the source of the leak and repair or replace the affected components.

Another common issue is brake fade. Brake fade occurs when the braking performance decreases over time or under specific conditions, such as prolonged braking or driving downhill. This can be caused by overheating of the brake components or worn brake shoes. To address brake fade, it is important to allow the brakes to cool down and avoid prolonged or excessive braking. If brake fade persists, it may be necessary to replace the brake shoes.

Frozen brake lines can also be a problem in cold weather conditions. When the moisture in the air brake system freezes, it can prevent the brakes from activating properly. To prevent frozen brake lines, it is important to use the appropriate air dryer system and perform regular maintenance to remove moisture from the system.

By being aware of these common air brake problems and knowing how to address them, you can ensure the continued safety and functionality of your air brake system.

Seasonal Maintenance for Optimal Air Brake Performance

In addition to regular checks and maintenance, seasonal maintenance is important for optimal air brake performance, especially in extreme weather conditions.

During the winter months, it is important to take extra precautions to prevent freezing of the air brake system. Inspect the air dryer system and replace any desiccant cartridges as needed. Ensure that the air lines and fittings are properly insulated to prevent freezing. Additionally, use the appropriate winter-grade brake fluid to prevent freezing of the brake lines.

In hot weather conditions, thermal expansion of the air brake system components can occur. This can lead to increased brake shoe-to-drum clearance and reduced braking performance. To prevent this, regularly inspect and adjust the slack adjusters to ensure proper brake shoe-to-drum clearance.

Seasonal maintenance also includes checking and adjusting the brake shoe lining thickness. In extreme weather conditions, the brake shoe lining can wear faster. Regularly inspecting the lining thickness and replacing the brake shoes as needed will help maintain optimal braking performance.

By performing seasonal maintenance tasks, you can ensure that your air brake system is prepared to handle the specific challenges posed by different weather conditions.

Professional Inspection and Maintenance: When to Call the Experts

While regular maintenance and checks can go a long way in ensuring the safety and performance of your air brake system, there are times when it is necessary to seek professional inspection and maintenance.

If you encounter any significant issues or problems that you are unable to address or diagnose on your own, it is recommended to consult a professional. They have the expertise and specialized tools to thoroughly inspect and diagnose any complex issues with your air brake system.

Additionally, it is important to adhere to any manufacturer recommendations for professional inspections and maintenance. These recommendations may include specific intervals for professional inspections or requirements for specific maintenance tasks. By following these recommendations, you can ensure that your air brake system receives the necessary professional attention to maintain its optimal performance and safety.

Remember, the safety of your vehicle and everyone on the road depends on the proper functioning of your air brake system. When in doubt, it is always better to seek professional assistance to address any concerns or issues.

Loading..

Loading..