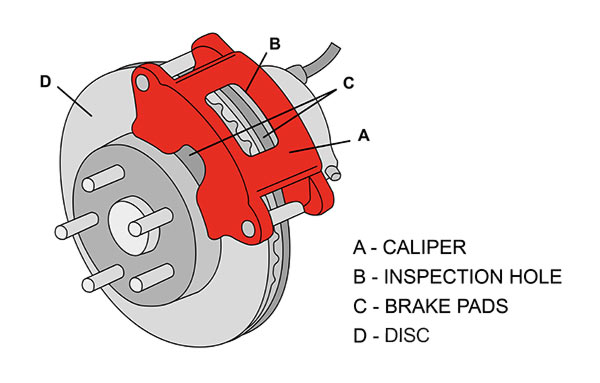

DISC BRAKE

Disc brakes are what ‘replaced’ drum brakes as the most popular choice for most cars. Drum brakes push out and this doesn’t create as much pressure as squeezing in on the wheel. So experts designed a system where something is squeezed rather than pressed. They also discovered that a greater surface area also means more friction and is vital for improving braking at high intensities. The combination of looking for something to squeeze and wanting high surface area led to disc brakes being adopted.

A disc brake is a mechanism for slowing or stopping the rotation of a wheel from its motion. A disc brake is normally made of cast iron, but in some cases, it is also made of carbon or ceramic composites. This is linked to the wheel and/or the axle. To stop the wheel, friction material in the form of brake pads is forced against both sides of the disc. Friction caused on the disc wheel will slow or stop.

Some discs have modifications to make sure that they cool down quicker and remain more effective. This is often achieved by letting air in, so modifications like a hole in the middle, small gaps around the outside, or fins will allow air to access the disc and ultimately mean a more efficient braking system

Loading..

Loading..