Comparing Hydraulic and Air Braking Systems

The critical differences and applications of hydraulic and air braking systems in today's vehicles.

The Basics of Hydraulic and Air Braking Systems

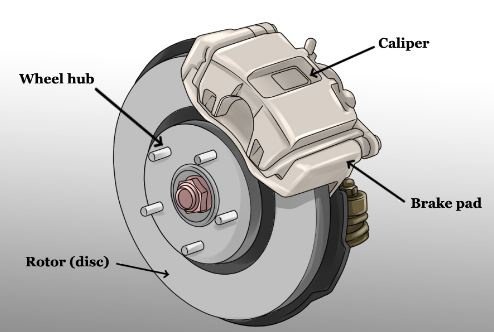

Hydraulic braking systems use fluid pressure to transfer force from the brake pedal to the brake pads, causing the vehicle to slow down or stop. This system relies on a master cylinder filled with brake fluid and connected to brake lines that lead to each wheel. When the brake pedal is pressed, the fluid is forced through the lines, applying pressure to the brake pads against the rotors.

Air braking systems, on the other hand, use compressed air to achieve the same result. This type of system is commonly found in larger vehicles such as trucks and buses. The air brake system consists of an air compressor, storage tanks, and air lines. When the brake pedal is engaged, compressed air is released, applying pressure to the brake pads or shoes.

Efficiency and Response Time in Braking Technology

The efficiency and response time of a braking system are crucial for vehicle safety. Hydraulic brakes are known for their quick response time due to the incompressible nature of brake fluid. This allows for immediate transfer of force, resulting in faster braking.

Air brakes, while effective, may have a slight delay due to the time it takes for air to travel through the system and apply pressure. However, advancements in air brake technology have minimized this delay, making them more competitive with hydraulic systems.

Maintenance Needs and Longevity Comparisons

Maintenance requirements for hydraulic and air braking systems differ significantly. Hydraulic systems require regular checks for fluid levels and potential leaks, as well as periodic replacement of brake fluid to maintain optimal performance.

Air braking systems, while generally more durable, require regular inspections of the air compressor, storage tanks, and air lines to ensure there are no leaks or blockages. They also need periodic draining of moisture from the air tanks to prevent corrosion and freezing in cold weather.

Safety Features and Performance in Adverse Conditions

Safety is a paramount concern when it comes to braking systems. Hydraulic brakes are typically reliable but can be susceptible to brake fade if the system overheats, which can occur during prolonged use.

Air brakes are designed with safety in mind, featuring fail-safe mechanisms that automatically apply the brakes if there is a significant loss of air pressure. This makes air brakes particularly advantageous for heavy-duty vehicles operating in challenging conditions.

Choosing the Right Braking System for Your Vehicle

Selecting the appropriate braking system depends on various factors, including the type of vehicle, usage, and maintenance capabilities. For most passenger vehicles, hydraulic braking systems offer a balance of efficiency, response time, and ease of maintenance.

For larger vehicles like trucks and buses, air braking systems are often the better choice due to their durability and fail-safe features. Ultimately, understanding the specific needs of your vehicle and consulting with a professional can help you make the best decision.

Loading..

Loading..