Demystifying the Role of Brake Linings

Explore the unseen but crucial world of brake linings and understand why they are pivotal for driving safety.

Understanding Brake Linings: Composition and Function

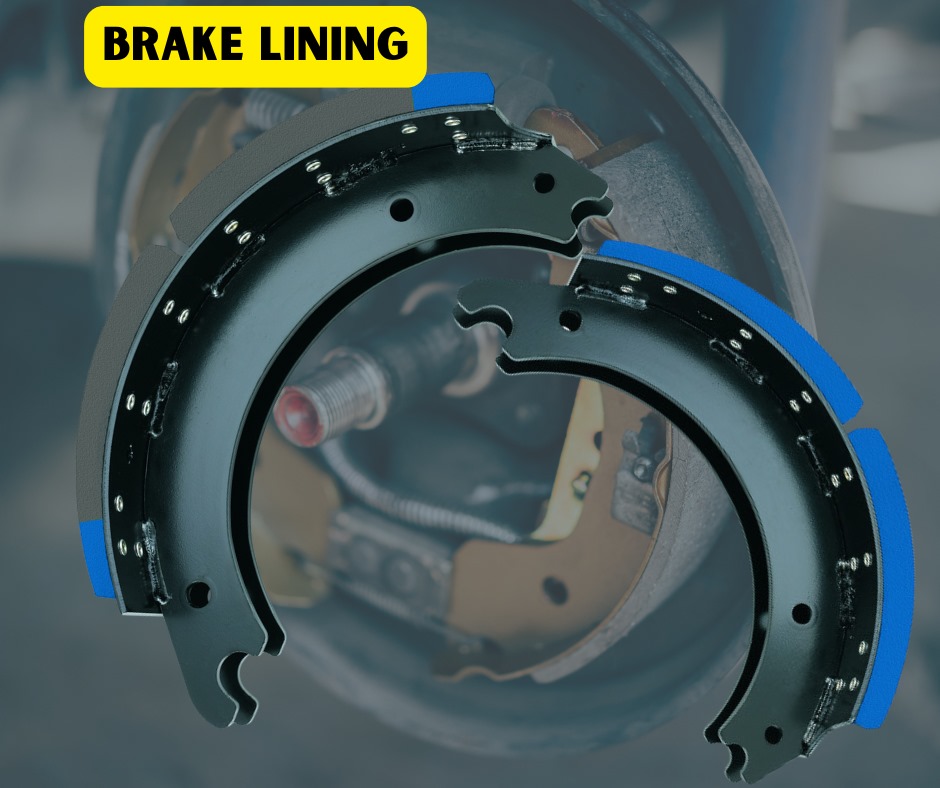

Brake linings are essential components in the braking system of vehicles. They are typically composed of materials that provide friction against the brake drum or disc, which helps in slowing down or stopping the vehicle. The composition of brake linings often includes a mixture of various materials such as rubber, glass, resins, and even metals. These materials are chosen for their durability, heat resistance, and ability to provide consistent friction.

The primary function of brake linings is to convert kinetic energy into thermal energy through friction. When the brake pedal is pressed, the brake linings are forced against the brake disc or drum, generating friction that slows down the wheel's rotation. This process is crucial for ensuring the vehicle can be controlled and stopped safely.

The Evolution of Brake Lining Materials

Over the years, brake lining materials have evolved significantly. Early brake linings were made from asbestos due to its excellent heat resistance and durability. However, asbestos was phased out due to its health hazards. Modern brake linings use safer and more environmentally friendly materials such as ceramic, semi-metallic, and organic compounds.

Ceramic brake linings offer high performance and produce less dust, making them a popular choice for many high-end and performance vehicles. Semi-metallic linings, made from a mixture of metals and other compounds, provide excellent durability and heat dissipation, suitable for heavy-duty applications. Organic brake linings, composed of non-metallic fibers, resins, and other fillers, offer a quieter and softer braking experience, ideal for everyday driving.

Key Factors Influencing Brake Lining Performance

Several factors influence the performance of brake linings, including material composition, temperature, and driving conditions. The material composition determines the friction coefficient, wear rate, and heat resistance of the brake linings. High-performance materials like ceramics and semi-metallic compounds offer better braking efficiency and longevity.

Temperature plays a crucial role in brake lining performance. Excessive heat can cause brake fade, reducing the friction and effectiveness of the brakes. Adequate ventilation and heat dissipation mechanisms are essential to maintain optimal brake performance. Additionally, driving conditions such as frequent braking, heavy loads, and high-speed driving can accelerate the wear and tear of brake linings, necessitating more frequent inspections and replacements.

Common Signs of Brake Lining Wear and When to Replace Them

It's important to recognize the common signs of brake lining wear to ensure timely replacements and maintain vehicle safety. Some common indicators include squealing or grinding noises when braking, reduced braking efficiency, and a longer stopping distance. A visual inspection can also reveal thin or uneven brake linings, indicating the need for replacement.

Most manufacturers recommend checking brake linings every 12,000 to 15,000 miles, but this can vary based on driving habits and vehicle type. If you experience any signs of worn brake linings or notice a decrease in braking performance, it's crucial to have your brakes inspected by a professional mechanic promptly.

Advancements and Future Trends in Brake Lining Technology

Brake lining technology continues to advance, with ongoing research focused on improving performance, safety, and environmental impact. Recent developments include the use of advanced composite materials that offer superior heat resistance and durability. These materials aim to provide better braking performance while reducing wear and tear.

Future trends in brake lining technology may include the integration of smart sensors that monitor brake lining wear in real-time, providing drivers with instant feedback and alerts for maintenance. Additionally, the push towards electric and hybrid vehicles is driving the need for specialized brake linings that can handle regenerative braking systems, which require different friction characteristics compared to traditional braking systems. As technology evolves, brake linings will continue to play a critical role in enhancing vehicle safety and performance.

Loading..

Loading..