Main functions of a piston in a car

Explore the vital roles that pistons play in powering your car's engine, ensuring efficiency and longevity.

Understanding the Role of Pistons in Car Engines

Pistons are integral components of an internal combustion engine, residing within the engine's cylinders. Their primary function is to convert the expanding force of combustion gases into mechanical energy that propels a vehicle forward. As the engine cycles through its four stages—intake, compression, power, and exhaust—the pistons move up and down, facilitating air and fuel intake, mixture compression, and exhaust gas expulsion. This continuous movement is the heartbeat of the engine, and without it, a car would not be able to operate. Understanding the role of pistons requires a basic knowledge of engine mechanics and the appreciation of precision engineering that goes into creating these powerful yet intricate devices.

In addition to converting energy, pistons also play a role in heat transfer. They absorb the heat generated by combustion and transfer it to the engine's cooling system. This process helps maintain an optimal operating temperature and prevents engine overheating. The piston's functionality is amplified by its close relationship with other engine components, such as the crankshaft, connecting rods, and cylinder walls. The synergy between these parts ensures that the engine runs smoothly and efficiently.

Transforming Fuel into Motion: How Pistons Work

The magic of an engine's power generation lies in the simple yet sophisticated movement of its pistons. When fuel is injected into the cylinder, it mixes with air and is ignited, causing a powerful explosion. This explosion creates rapidly expanding gases which push the piston downward in a stroke known as the 'power stroke.' As the piston moves down, it turns the crankshaft, which ultimately leads to the rotation of the car's wheels. This transformation of linear piston motion into rotational force is the foundation of how vehicles move.

The piston's work doesn't end there. Once the power stroke is complete, the piston must move back up to expel the exhaust gases produced during combustion. This upward motion, referred to as the exhaust stroke, clears the cylinder for the next cycle. Pistons are constantly moving up and down, and their speed and precision are critical for optimal engine performance. It's a dance of metal choreographed by the laws of physics, where every movement counts.

The Impact of Piston Design on Engine Performance

Piston design is a crucial factor in engine performance. The weight, shape, and material of a piston can greatly influence an engine's power output, efficiency, and durability. Lightweight pistons, for example, allow for faster movement and can lead to higher engine speeds, which translate to more power. Additionally, the design of the piston's top, or crown, affects how air and fuel mix and how efficiently combustion occurs. Advanced designs may include features like recesses or domes that optimize this process.

Materials also play a significant role. Pistons must withstand extreme pressures and temperatures, and their construction often involves robust materials such as aluminum alloys. These materials are chosen for their ability to handle high stress while minimizing weight. Moreover, surface treatments and coatings can reduce friction and wear, enhancing the piston's lifespan and the engine's overall reliability. The meticulous design of pistons is a testament to the complex engineering required to keep modern engines running at peak performance.

Maintaining Your Car's Pistons: Best Practices

To ensure that pistons function effectively over the lifespan of a vehicle, proper maintenance is essential. Regular oil changes are critical, as clean, high-quality oil lubricates the pistons, reducing friction and wear. It's also important to keep the engine running at the correct temperature, which means maintaining the cooling system and making sure the coolant levels are adequate.

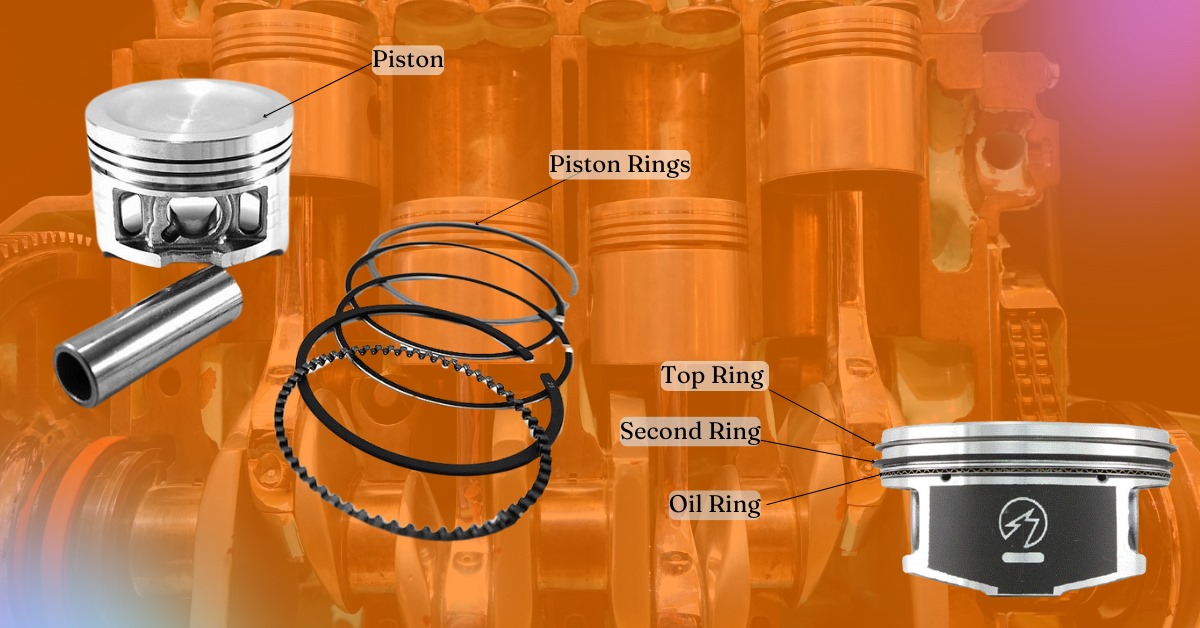

Additionally, using the correct grade of fuel can prevent knocking, which can cause damage to the piston crowns. Adhering to the vehicle's service schedule allows for timely detection and replacement of worn components, such as piston rings or bearings, which can affect piston performance. By following these best practices, car owners can help extend the life of their engine and avoid costly repairs down the line.

Future Innovations in Piston Technology and Materials

The automotive industry continuously explores new technologies and materials to enhance piston performance. Innovations in piston technology are geared towards increasing efficiency, reducing emissions, and improving durability. One area of research is the development of new alloy compositions or composite materials that can withstand even higher temperatures and pressures while maintaining or reducing weight.

Another promising field is the use of surface treatments and coatings that can further reduce friction and wear, thus improving fuel efficiency and engine life. Additionally, advancements in 3D printing may pave the way for more complex piston designs that were previously not feasible with traditional manufacturing methods. These innovations are part of the broader effort to meet stricter environmental regulations and consumer demands for more powerful and efficient vehicles.

Loading..

Loading..